TECHNOLOGY

We handle different compounds, coming entirely from italian suppliers, like for example: NBR, HNBR, FKM, EPDM, AEM ACM,VMQ, silicone and food rubber compounds.

Our machine fleet, consisting of injection moulding machines ranging from 80 to 500 tons, allows us to produce a wide range of items, from less than a gram up to 3/4 Kg. We also have a rotary 4.0 oven for the post-vulcanization, so that the characteristics of the material used can be fully reproduced.

MOLDS MAINTENANCE

For the maintenance and cleaning of the moulds, we use an ultrasonic immersion tank and a sandblasting machine.

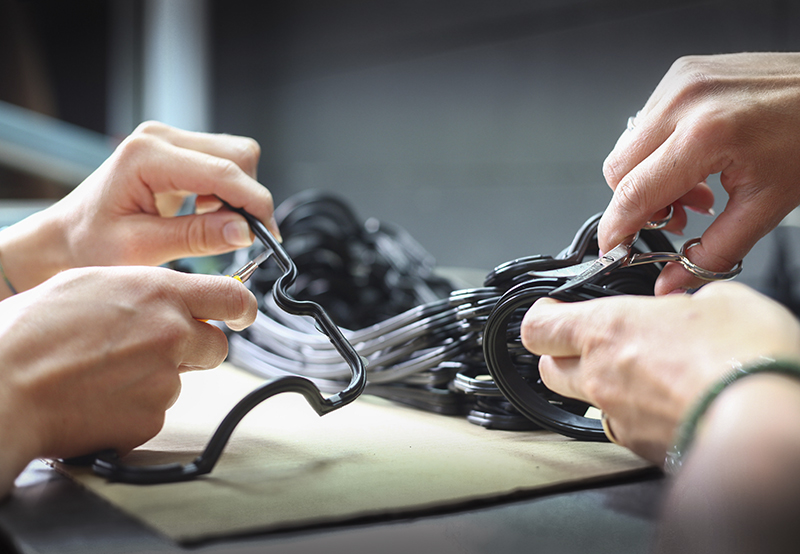

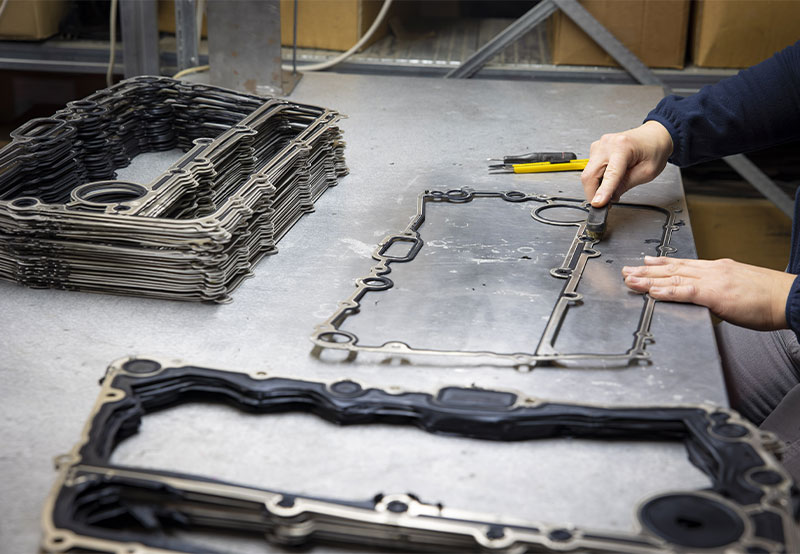

TESTING DEPARTMENT

Our visual and manual testing department checks and intercepts any non-conformity on the product, before deliver it to the customer.

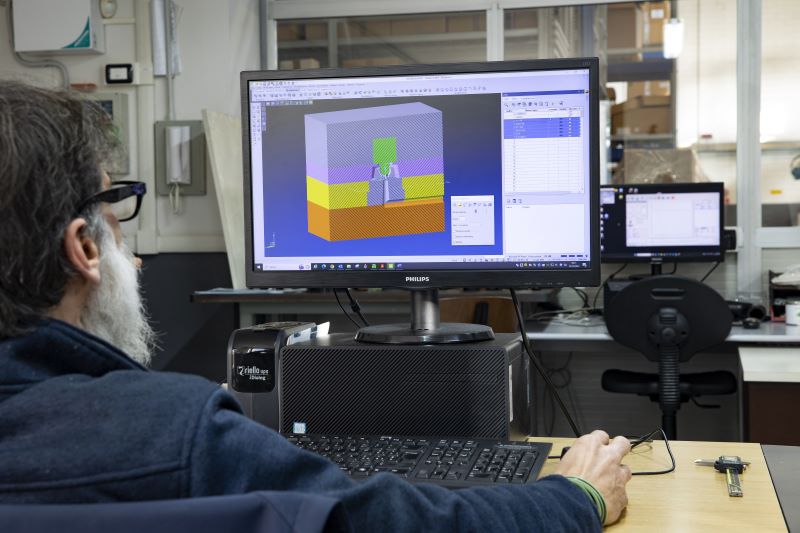

LABORATORY

In our laboratory we perform:

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie records the user consent for the cookies in the "Advertisement" category. |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| CookieLawInfoConsent | CookieLawInfoConsent | CookieYes sets this cookie to record the default button state of the corresponding category and the status of CCPA. It works only in coordination with the primary cookie. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| wpEmojiSettingsSupports | session | WordPress sets this cookie when a user interacts with emojis on a WordPress site. It helps determine if the user's browser can display emojis properly. |

| Cookie | Duration | Description |

|---|---|---|

| pll_language | 1 year | Polylang sets this cookie to remember the language the user selects when returning to the website and get the language information when unavailable in another way. |